Oregon policies support renewable energy, but not all green energy technologies are created equal.

Converting waste heat into energy is an eco-friendly technology arguably better suited to dense downtown areas in the Pacific Northwest than wind and solar-powered systems.

Waste heat recovery, however, does not qualify for state and federal green energy incentives. These programs prioritize wind and solar over emerging technologies, a practice some activists and politicians say stifles clean tech innovation.

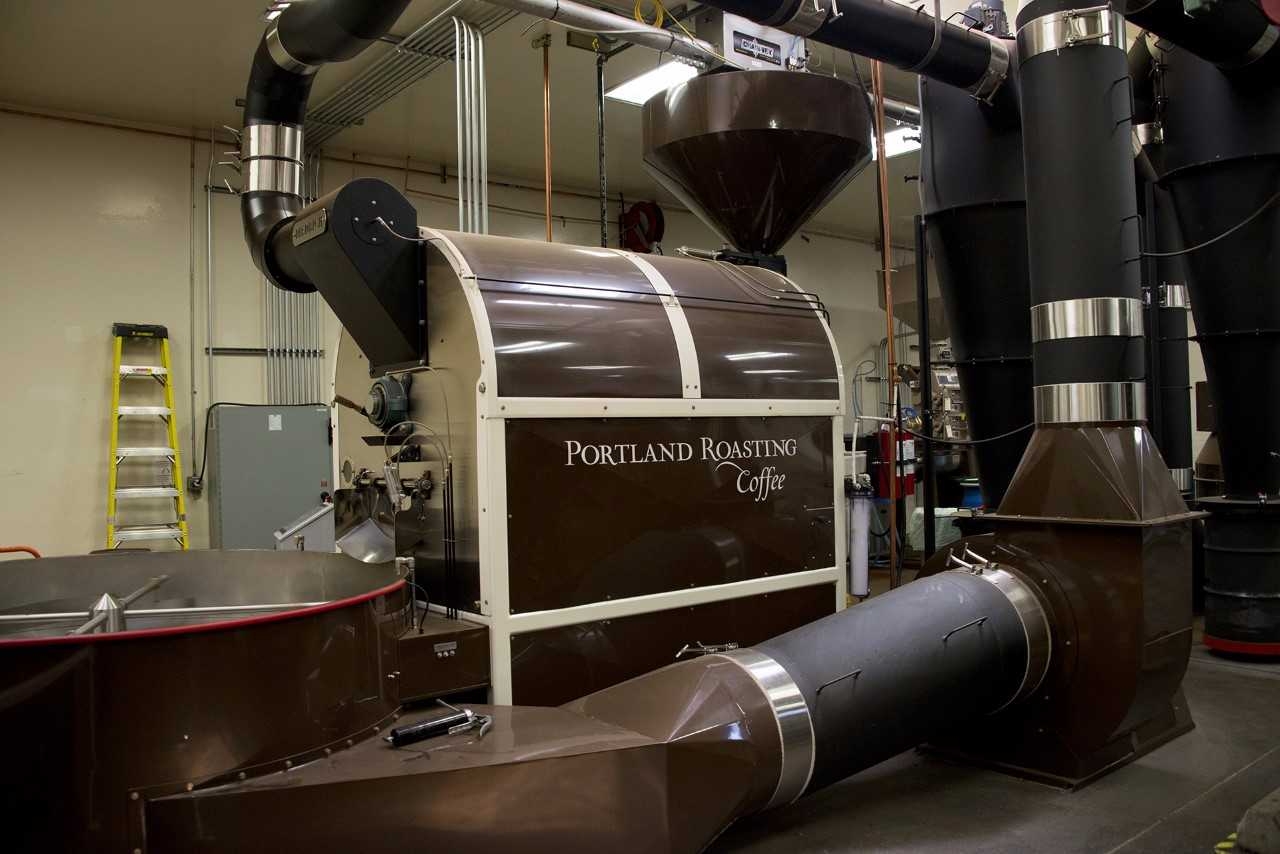

Portland Roasting Coffee, based in downtown Portland, plans to install a device that captures heat from roasting and emission control to spin a turbine that generates electricity. The heat recovery system will produce up to 25 kilowatt-hours of power while the roaster operates, offsetting the roasting facility’s power consumption by around 25%. Stell plans to have the system operational by the end of the first quarter in 2018.

“We can’t do wind in the city,” said Mark Stell, managing partner and owner of Portland Roasting Coffee. “Solar is great, but it’s just not for this area, and not for manufacturing,” This technology [heat recovery] is perfect for us.”

Waste heat to Power (WHP) offers downtown manufacturers several advantages over solar or wind. In crowded downtown areas, WHP occupies less space. Unlike solar, WHP can generate electricity all day long in the perpetually cloudy Pacific Northwest. If a business relocates, it’s easier to move a waste heat generator than to unbolt solar panels from a roof.

The roaster Portland Roasting plans to connect to heat recovery technology / Portland Roasting Coffee

The roaster Portland Roasting plans to connect to heat recovery technology / Portland Roasting Coffee

Sam Weaver, CEO of Cool Energy, Inc., which designed the system for Portland Roasting Coffee, said the engine runs at up to 30% efficiency. That means 30% of the energy in the heat the roaster emits turns into useable electric energy.

Stell has encountered several obstacles while trying to get tax credits for the clean power his facility generates. The Oregon Department of Energy conservation tax credits sunset this year. Oregon HB 2680, a bill that would have expanded the definition of credit-worthy renewable energy production systems to include “systems that use waste heat,” died in committee this summer.

In addition, waste heat to power systems don’t qualify for Oregon’s net metering law, which pays solar users for excess electricity they send back into the grid.

Jennifer Kalez, Public Affairs & Outreach Coordinator at ODOE, said she was not familiar with any Oregon incentive programs for waste heat to power.

“For this energy technology to take off,” Stell said, “you need to have state and local buy in.”

Stell said he doesn’t know of any other Oregon companies using the new heat recovery system, although a few steel companies are using older Stirling Engines, a similar, but much less efficient, technology.

Portland Roasting Coffee did qualify for a $20,000 grant from the Energy Trust of Oregon. And though it doesn’t include WHP, an ODOE program rewards a wide range of renewable technologies with competitive grants of up to $250,000 for “biomass, solar, geothermal, hydroelectric, wind, landfill gas, biogas, and wave, tidal, or ocean thermal energy.”

Stell’s company has sent letters to state senators asking them to support Waste Heat to Power.

Senator Ron Wyden introduced the “Clean Energy for America Act” in May, which would provide incentives for companies based on their ability to reduce emissions, regardless of the technology they use. The advocacy group Heat is Power circulated a letter among business owners and politicians to garner support for the bill. China operates 739 Waste Heat to Power systems in the cement industry alone, the letter notes, while the U.S. has 96 such systems across all industries.

“WHP implementation is lagging because current U.S. tax policies incent known technologies rather than encourage innovation and new approaches through mechanisms such as technology neutral tax policies,” wrote Susan Brodie, executive director of Heat is Power.

“Current U.S. tax policies incent known technologies rather than encourage innovation and new approaches”

—Susan Brodie, executive director of Heat is Power

In addition to regulatory hurdles, WHP still faces technical challenges, an EPA study notes. Heat sources often spew contaminates that complicate the recovery process. A plant might also emanate heat from several dispersed sources, so it can be difficult to consolidate and capture.

Stell says Portland Roasting Coffee will move forward with plans to add a second roaster with the heat recovery technology by the end of this year, regardless of the incentives. But for widespread adoption to occur, he says, the technology needs public assistance.

The Energy Trust grant reduced his return on investment for the first roaster from around eight years to 6.5, but a federal tax credit could have dropped it to 4 years.

“For this energy technology to take off,” Stell said, “you need to have state and local buy in.”