An under-the-radar industry fuels local and state fire fighting efforts.

Wildfires get all the attention. Fire fighting equipment companies, not so much.

“People really don’t know what we do,” says Jeff Lloyd, sales manager at Cascade Fire Equipment, a Medford-based company. “It’s so niche.”

Cascade Fire Equipment runs an industrial sewing facility.

Cascade Fire Equipment runs an industrial sewing facility.

Founded by Lloyd’s grandfather, Dan Lloyd, in 1985, Cascade makes and sells a wide variety of products: clothing, pumps, vehicles, extinguishers and more.

Revenues have been on a steady incline over the past five years. During the period 2008-2013, Cascade grossed around $6 million annually. Last year it was over $14 million.

The economic recovery helped fuel the uptick in sales. Longer, hotter wildfire seasons are also boosting business.

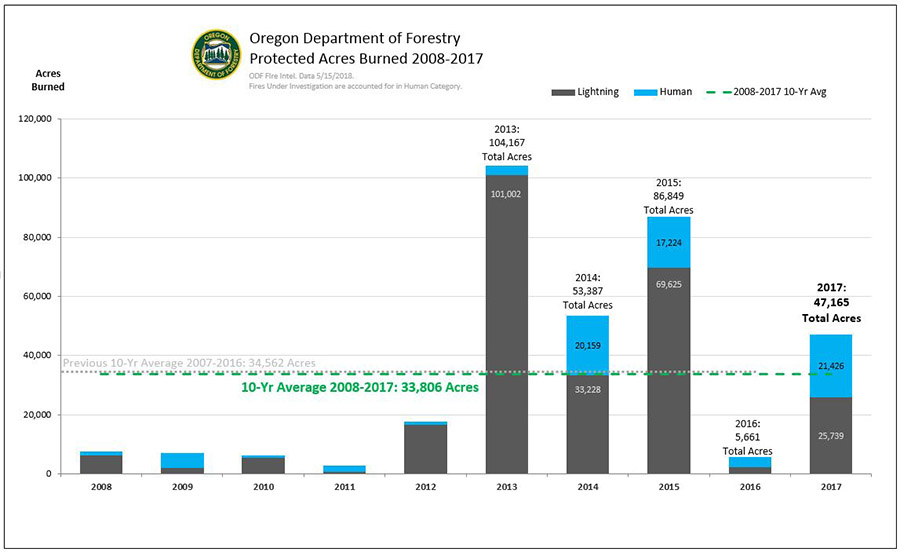

So far this year, the Oregon Department of Forestry estimates the state has already exceeded the number of acres burned in 2017, says spokesperson Jim Gersbach. The latest figure is 56,200 acres burned.

Business is up 20% over last year, says Shannan Mills, division manager for National Firefighter, a Eugene-based distributor. “Demand has been really high this year. It’s a very busy season.”

The company employs 11 people in its wildland fire division.

About 50 people work in the Cascade Fire machine shop. The family-owned business also operates an industrial sewing facility to make clothing it sells under the Strike Team brand.

Like most manufacturers, Cascade Fire struggles to find skilled workers. “We have a really hard time finding welders,” Lloyd says. “And it’s almost impossible to find people who have experience on industrial sewing machines.”

The company hires people whom they think will be a good fit, then provides training on site.

Cascade Fire Equipment

Cascade Fire Equipment

As wildfires encroach on urban areas, Cascade is ramping up business with districts that typically focus on structural fires, Lloyd says. Plus, reciprocity agreements between Oregon and other states mean that local fire districts are sending personnel to fight wild land fires.

Last year was the first year the Medford fire department sent fire fighters to California, says the city’s deputy fire chief Justin Bates.

Contractors and individual fire districts typically bear the cost of equipment and clothing purchases, Gersbach says. So it’s difficult to put a figure on the statewide equipment and clothing budget.

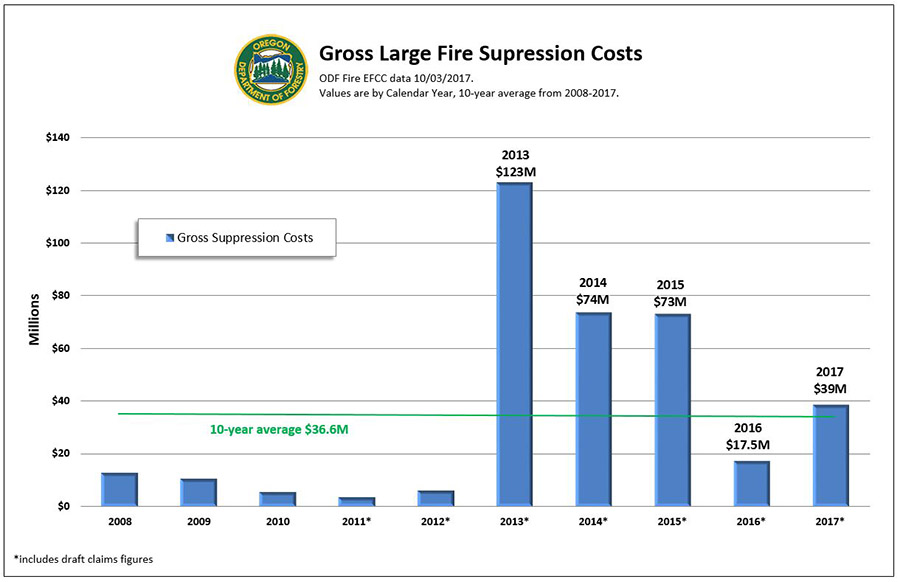

But as wildfires have gotten larger, he says, overall expenses have risen.

The cost of fighting large fires was $39 million in 2017, compared to $10 million in 2008. The state defines large fires as 100-plus acres of timber or 300-plus acres of grassland.

As fires burn hotter, innovation is coming is coming to the sector. The U.S. Forest Service Technology and Development Center in Missoula is testing a new fire shelter that will hold up under more heat, Mills says.

The industry is moving toward more breathable garments. In the 1990s, according to Lloyd, clothing technology revolved around protecting fire fighters from thermal exposure. When more firefighters started dying from heat stress, the standards changed to allow for more permeable gear.

As fires burn in higher density areas, state and federal forest service departments are also leaning toward smaller, easier to maneuver vehicles, he says.

These technology trends point in one direction. Fire fighting equipment is a challenging business, Lloyd says. “In the winter, work slows down, then it gets crazy in the summer time.”

But the seaon is changing, he says. “It’s getting longer.”

To subscribe to Oregon Business, click here.