Set against the dry blue sky and bleached hills on the outskirts of town, the 100-year-old Pendleton Woolen Mills is an icon to the town and a brand that is the essence of Americana. But to its president, it’s also something more visceral.

Set against the dry blue sky and bleached hills on the outskirts of town, the 100-year-old Pendleton Woolen Mills is an icon to the town and a brand that is the essence of Americana. But to its president, it’s also something more visceral.

|

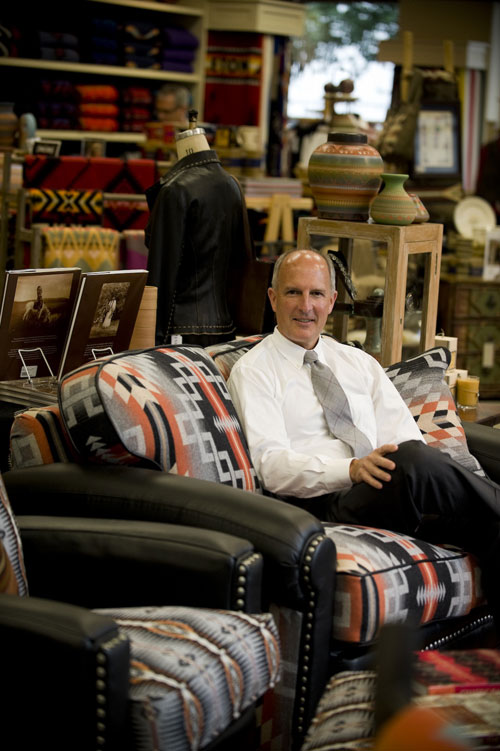

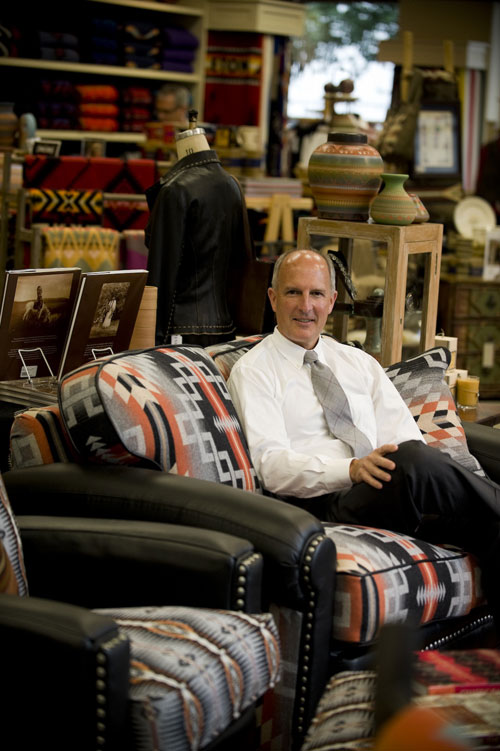

PRESIDENT: Mort Bishop III |

Set against the dry blue sky and bleached hills on the outskirts of town, the 100-year-old Pendleton Woolen Mills is an icon to the town and a brand that is the essence of Americana. But to its president, it’s also something more visceral.

“You open the door of the store and you get a waft of wool smell — it’s just like smelling leather, ” says Mort Bishop III. “You smell quality.”

There is also a whiff of nostalgia for Bishop.

“One hundred years ago there were 1,000 mills,” he says. “Now there are only a handful.”

As one of the few left standing, Pendleton is coping with the recession and a changing market that over the past decades has seen wool blankets go from an everyday necessity to a specialty product. Pendleton has adapted by creating bedding out of other fabrics and designs. Even though Pendleton is the largest blanket manufacturer in the country, clothing is now 80% of its business. It processes and weaves all its wool at mills in Pendleton and Washougal, Wash.

Over the past decade that Bishop, 57, has been president of this sixth-generaton family business, the company has changed its focus from wholesale to retail, doubling its retail stores. Pendleton now has 70 retail outlets across the U.S. and also sells in Canada, China and Japan. While 45% of sales are still wholesale to department stores such as Dillards and VanMeur in the Midwest, 55% of sales are now catalog, Internet and retail.

But with gross revenue flat, Pendleton this summer eliminated 45 jobs, consolidated yarn manufacturing at the Washougal mill, and plans to cut salaries that are more than $50,000 annually. But Bishop is optimistic that consumer confidence will improve by fall and sales will pick up. The company has also refocused on core products, such as women’s jackets and skirts, and men’s shirts and sweaters.

Pendleton competes with Talbots and J. Crew for the attention of the 45- to 55-year-old shopper with a taste for quality fabrics. Balancing reliable products and innovative designs is the challenge Pendleton Woolen Mills faces every year. Bishop anticipates the market six months in advance, what he calls, “writing the next chapter.”

“The next chapter has to fit logically after the existing chapter in the book,” he says. “It all has to work together in a cohesive way.”

|

|

|

In the next chapter, he sees collaborations as key to creating innovative new designs — and staying in business. A collaboration with the high-fashion New York-based company Opening Ceremony landed a Pendleton jacket on the May cover of American fashion bible Women’s Wear Daily. And it started, of all places, in Japan. There, American styles have been tweaked to fit Japanese frames and sensibilities, inspiring a new line of clothing called Pendleton Meets Opening Cermony, which uses Pendleton wool and Native American patterns in clothing with urban styling. Two other collaborations, one with clothing company Hurley and one with the Japanese high-fashion label Comme des Garçons, also combine Pendleton fabric with new cuts and styles. These lines launch this fall.

“Our business niche is classic merchandise, but even in classic merchandise there needs to be freshness, evolution and creativity,” says Bishop.

As Pendleton celebrates its centennial anniversary this year, Oregon turns 150. It was a custom Pendleton blanket that Gov. Ted Kulongoski gave to President Barack Obama to celebrate the state’s anniversary, a blanket picturing Mt. Hood that was made from a new wool derived from environmentally friendly processes and dyes.

But sustainability isn’t just a green manufacturing process for Bishop.

“I was well-trained by my father and grandfather and uncle,” says Bishop. “That comes with a certain level of responsibility to leave the company better than you found it.”