Schoolhouse Electric & Supply Co. founder Brian Faherty grows a lifestyle brand, boosting the fortunes of local manufacturers along the way.

Schoolhouse Electric & Supply Co. founder Brian Faherty grows a lifestyle brand, boosting the fortunes of local manufacturers along the way.

BY LINDA BAKER

|

|

Schoolhouse Electric founder and owner Brian |

“I know it’s kind of Portlandia-ish, but it’s a really good thing for me.” Brian Faherty, founder and owner of Schoolhouse Electric & Supply Co., is sitting in what he refers to as his “digital-free room,” a refurbished shipping-foreman’s office located in the company’s headquarters in Northwest Portland’s industrial district. No cell phones or digital devices of any kind are allowed inside the small space, which features brick walls, a wood stove and an axe, artfully buried in a stack of logs.

It all looks very Little House on the Prairie. “It does, doesn’t it?” responds the 49-year-old Faherty, his face lighting up. He pulls out two bottles of Bolle water, encased in a sleek glass design. “It’s my favorite water,” he says. “The bottle is kind of cool.”

Faherty sits at the helm of Schoolhouse Electric. But he is the first to tell you his passion is design, not business. He’s also the first to tell you, digital-free room notwithstanding, that he isn’t interested in copying the past. On the contrary, Faherty has spent the past 10 years transforming his nostalgia for an earlier era into a business that is decidedly future oriented. Founded in 2003, Schoolhouse Electric has grown from a small shop reproducing period light fixtures into a national housewares and furnishings brand that grew 70% last year and is on track to grow 30% in 2013.

Today, as the company celebrates its 10th anniversary, Faherty is at a crossroads — a business crossroads. “We’re in the rapids right now,” he says. “We’re experiencing a lot of velocity and it’s hard.” It’s a challenge that goes beyond managing the company’s accelerating growth. A Portland native and one of a signature breed of humble and self-effacing Oregon businesspeople, Faherty is driven by another imperative: to implement workplace and business practices that are as durable and useful as the interior furnishings the company sells.

Increasingly, that effort focuses on support for homegrown manufacturing and a call for local and state governments to move beyond what Faherty perceives as a narrow business retention and recruitment focus on green and tech industries. “How many app companies can you have?” Faherty asks. “Really, is that the future?” The City of Portland, he says, should target the “local maker movement, putting smaller companies like ours together, investing in us and what we can use.”

“Think what that could do to the local economy and manufacturing.”

|

Schoolhouse Electric employees Yoslenys Hernandez-Torres, Prithi Sarki (above) and Salvador Gomez (below) assemble fixtures in the company’s Northwest Portland headquarters.// Photos by Eric Näslund |

|

Before there was Schoolhouse Electric, Faherty worked on the other side of the home-furnishing economy: buying, refurbishing and selling houses. This was during the restoration craze, and Faherty, who has lived in 12 houses in the past 25 years, noticed there were limited quantities of certain materials and products, especially lighting and, notably, “cool, glass schoolhouse fixtures.”

After researching the American glass-blowing industry, he stumbled on a company in upstate New York with a warehoused collection of cast-iron molds for hand-blown glass lighting. “So I bought the collection and had them restored and put back in production. I knew I had something that was the start of something. There was some authenticity around the process and the material, and that was the thing I was looking for.”

That’s how it all began. Faherty opened a small storefront on Northeast Martin Luther King Boulevard and eventually rolled out a collection of 100 pieces, putting the glass together with brass parts made in Los Angeles. As the business grew, the design evolved too; instead of fashioning look- alike period reproductions, Schoolhouse began to experiment with a more modern aesthetic, “such as Edison bulbs on sockets or grouped in nature,” Faherty says.

With only three employees, Schoolhouse Electric had no marketing department to speak of. Even today Schoolhouse remains an introverted company, Faherty says. “We don’t really know how to talk about ourselves. That’s probably because I’m sort of that way.”

But if Faherty is reticent, the home design bloggers who created a cultural zeitgeist starting around 2008 were not. Schoolhouse Electric “became the little darling” of Remodelista and Design Sponge, among others, Faherty says. And business began to take off.

The momentum inspired Faherty to expand the company to include home furnishings. “What was serving the market was big-box, corporate housewares companies, and our customer wants more authenticity. They want to know who made it and what was the inspiration.” So in 2010 Faherty purchased a four-story, 125,000-square-foot brick warehouse in Northwest Portland for about $1.5 million, remodeled it to house a flagship store, as well as a factory and office space, then launched Schoolhouse Electric as a comprehensive lifestyle brand selling home and office goods.

The catchall description for the Schoolhouse Electric style is “domestic utility,” Faherty says. “Not just pretty things, but things that are useful in everyday life.”

|

“When it comes to furniture, I’m more into hard stuff than soft,” Faherty says. “I’m really into clocks right now.”// Photos by Eric Näslund |

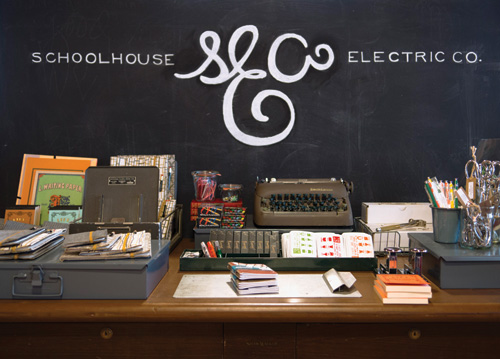

Inside the Northwest Portland store (a second showroom is in New York), domestic utility is on full display: baskets, rugs, toothbrush holders, beds, couches, all featuring a clean, spare aesthetic with a hint of nostalgia. Behind the scenes — on the second floor, to be precise — another kind of utilitarian philosophy is at work. But first, a disclaimer: Schoolhouse Electric is less a manufacturer than an assembler. Most of the retailer’s metal light fixtures, for example, are made by several factories in Los Angeles and then sent to Portland, where Schoolhouse employees paint, finish and assemble the final product.

The company purchases other products crafted by vendors, then adds value; Faherty might take a stool and paint it in Schoolhouse colors or remake the standard IBM clock with the word “Schoolhouse” in the design.

“We’re really into micro-manufacturing: Who are those small makers of things that can have a voice even if it’s through us?” Faherty says, adding that even if many Schoolhouse component parts aren’t made in-house, neither are they “off the shelf” parts made in China. In Portland, Schoolhouse works with about 50 local vendors, such as Mudshark Studios, which crafts most of Schoolhouse Electric’s ceramic shades, including the Alabax pendant and Ion lamp. “What’s important is that our vendors are our partners,” says Faherty, “and that we can see their shop and how they treat their workers.”

He recounts a story of a light fixture he saw at Urban Outfitters that cost $20. “Working backward, they’re not making it; they’re buying it from somebody for $10 who probably bought it for $5. How do you do that? It’s junk and probably made under conditions that aren’t really esteemable.”

A Schoolhouse fixture might cost more — $189 for the Alabax — but that’s because the labor is more expensive, says Faherty. He pays Schoolhouse Electric’s 35 assembly workers, many of whom are referred by IRCO — the Immigrant & Refugee Community Organization — about $9-$20 per hour with benefits and health insurance. Schoolhouse Electric employs a lot of families, Faherty adds: a few brothers and sisters and one family with three generations. “These are good jobs,” he emphasizes. “They are nothing to be ashamed of.”

Mudshark boosted employment from 8 to 27 workers last year, in part because of business generated by Schoolhouse Electric, says co-owner Brett Binford. “Brian’s one of about 10 steady producers who provide stable employment,” he says. “He holds American-made in high principle.”

Faherty’s tenant-screening philosophy revolves around a similar maker sensibility. So far he has leased space to Ristretto Roasters, Anna Mara Floral Design, Egg Press, (a letterpress studio), and Ben Waechter, a local architect who two years ago designed the Scandinavian farmhouse-style Dunthorpe house that Faherty lives in with his wife, Jill, who works in product development at Schoolhouse, and their three children.

“Setting up a studio in this building appealed to me because it’s a factory filled with people making things,” Waechter says. Faherty, he adds, was very active in the home-design process, with a clear idea of the character, atmosphere and material palette he wanted to achieve.

“I collaborate with people,” says Faherty, describing his approach to projects, personal and professional. “I have to work like that. I have to be involved.”

|

Lighting still accounts for a majority of Schoolhouse Electric sales. “It’s our bread and butter,” Faherty says.// Photos by Eric Näslund |

Eighteen months ago, Schoolhouse Electric employed 26 workers; today the staff count is 56, and by the end of the year it will be 65. The company recently hired two marketing associates and a warehouse manager and is searching for a human resources director. About 100 orders come in daily, up from 50 just two years ago. “It’s crazy!” Faherty says. He declines to reveal revenues, noting only that the Schoolhouse website accounts for about 60% of gross revenue and that 30% of sales comes from the trade market, including stores and hotels.

The company’s rapid growth trajectory means the business side is getting more complicated, and Faherty is quick to say he’s much better at making money than keeping track of or managing it. (He doesn’t own a checkbook, and an accountant pays most of the household bills.)

Friends and colleagues say the Schoolhouse founder is too modest about his business acumen. “Brian has a knack for evaluating both the home and lifestyle market and identifying where the holes are, then trying to fill that need,” says longtime friend Lance Marrs, a realtor who worked with Faherty on several revitalization projects the two men co-own, including the Commodore Hotel in Astoria and the bSIDE6, a Portland office building.

It was during the recession, Marrs adds, that Faherty had the foresight to reposition the company as a lifestyle brand.

Faherty is a visionary thinker, agrees Sarah Culbertson, Schoolhouse managing director. She cites as an example a recent decision to redo the New York showroom. The team didn’t hire an architect and designer to build a new store, Culbertson says. Instead, Faherty decided to remodel the showroom entirely from pieces culled from the Schoolhouse Electric building and Faherty’s old house, using everything from old flooring to parts from metal bookcases.

“He’s a risk taker,” Culbertson says. “He comes up with an idea that seems way out there but turns out to be a pretty ingenious way to make sure the brand vision is present throughout.”

Today Faherty’s strategy for preserving the Schoolhouse brand revolves around “managing growth while maintaining our values: how we manufacture and how we innovate.” With the help of a consultant, Schoolhouse is reorganizing factory production to be more efficient, moving away from what Faherty describes as an individual craftsman approach to a clustered or “cell” structure resembling an assembly line. He wants to bring more manufacturing in-house — he recently brought in a sewer for textiles — and open additional retail stores, perhaps starting with San Francisco.

Here’s where Faherty’s critique of local business policy enters the picture. Grappling with growth, he would like assistance from the city — with workforce training, with taxes, even help developing vendors, many of whom are struggling to accommodate Schoolhouse Electric’s growing demand.

On the one hand, the timing seems right. In the past few years, small-scale local manufacturing has been making a comeback; witness the launch of Portland Made last year, a collective of local designers, goods retailers and builders. And several Oregon-based manufacturers recently moved their operations from China back to the United States, including Handful, a sports bra manufacturer, and Trellis Earth Products, a maker of disposable bioplastic plates and garbage bags. On the other hand, despite the forward movement, public policies still tend to ignore smaller, local manufacturers and assemblers such as Schoolhouse in favor of larger firms such as Vestas “that then fail,” Faherty says. “It’s a real blind spot,” he laments. “We’re small so they look at us like, ‘You’re on your own.’ I’d like to see some fresh thinking: what can the city learn from successful manufacturers, and how can they help ones like us sustain our business?”

Faherty is in his office, not the digital-free room but his primary workspace, which contains an original grid map of North Portland’s Holy Redeemer Parish before the I-5 freeway was built in 1964. That stretch was called the Minnesota freeway because it ran through a street by that name, he remarks. “Isn’t that funny? I love looking for old stuff.”

A designer and renovator interested in the provenance of things, Faherty isn’t a politician; he isn’t the CEO of a big company. But he is part of a new generation of businesses that are quietly becoming a cultural and economic force in Portland and Oregon. Whether he’s retooling lighting, clocks or local manufacturing, this creative director and small-business owner is helping lead a decidedly modern movement: making everything old new.